#Civil_Engineer_ညီငယ္ညီမငယ္မ်ားအတြက္

#DeckingSheet with Shear Stud အၾကံျပဳ ခ်က္(၉)ခ်က္။

1. Decking Sheet ဆိုသည္မွာ

dacking sheet ကို၊ aluminum ျဖင့္လည္းေကာင္း၊ zinc galvanized steel

ျဖင့္လည္းေကာင္း၊ ျပဳ လုပ္ထားၿပီး၊ ၄င္းသည္ ၾကံ့ခိုင္ျခင္း၊

ဒူေပဒါေပခံျခင္းတို႔ေၾကာင့္၊ floorမ်ား၊ roof မ်ား တည္ေဆာက္ရာတြင္၊

platform = ေအာက္ခံ အျဖစ္၊ အမ်ားအျပား အသံုးျပဳ ၾကပါသည္။ ထို႔အျပင္၊ ကုန္က်

စရိတ္လည္း၊ သက္သာ ေစပါသည္။

Decking Sheet၏၊ အားသာခ်က္မ်ားမွာ။

1.1 Concrete volum ကို၊ ေလ်ာ့ခ်ႏိုင္သည္။

1.2 temporary formwork စရိတ္ကို၊ ပယ္ဖ်က္ႏိုင္သည္။

1.3 လုပ္ငန္းစဥ္ေလ်ာ့သြားသည့္အတြက္၊ တည္ေဆာက္စရိတ္ကို၊ ေလ်ာ့ခ်ႏိုင္သည္။

1.4 လြယ္ကူလ်င္ျမန္စြာ၊ တပ္ဆင္ႏိုင္သည္။

1.5 သိုေလွာင္စရိတ္မရွိေပ။

2. Shear stud ဆိုသည္မွာ

Shear stud ဆိုသည္မွာ၊ concrete slab ႏွင့္ steel beam တို႔၏၊

အဆက္အစပ္သည္၊ shear loading ကိုခံႏိုင္ ေအာင္၊ တနည္းအားျဖင့္၊

ပြတ္တိုက္ေရႊ႕လ်ားမႈမျဖစ္ေအာင္၊ တခုႏွင့္တခု ဆက္စပ္ခိုင္ျမဲသြားေစသည့္၊

အရာျဖစ္ သည္။ အမ်ားသေဘာပါေအာင္၊ ေျပာရမည္ဆိုပါက၊ သစ္သားၾကမ္းခင္းျပားကို၊

ဆင့္ႏွင့္ သံစြဲသကဲ့သို႔၊ dacking sheet အေပၚက၊ ကြန္ကရစ္ၾကမ္းခင္းကို၊

dacking sheet ေအာက္က၊ သံယကၼႏွင့္ သံရိုက္ေပးလိုက္ျခင္း သေဘာ ေပတည္း။

2.1 Shear Stud ကို steel ျဖင့္ျပဳလုပ္ထားပါသည္။ ဝယ္ယူသည့္အခါ ceramic

ferrule - ေျမက်က္ကရြတ္ျဖင့္၊ တြဲ လ် က္ဝယ္ယူရပါသည္။ ဝရိန္ေဆာ္သည့္အခါ Stud

ႏွင့္ beam တို႔၊ တြဲဆက္မႈ ေသခ်ာေစရန္အတြက္၊ ceramic ferrule ကို၊

အသံုးျပဳ ရျခင္း၊ ျဖစ္ပါသည္။

2.2 shear Stud ကို၊ အရွည္ႏွင့္အရြယ္အစား အမ်ိဳးမ်ိဳး ဝယ္ယူရရွိႏိုင္ပါသည္။

2.3 ဝရိန္တို႔သည့္အခါ၊ shear Stud ၏၊ အလ်ားသည္ 5mm ခန္႔၊ တိုသြားတပ္ပါသည္။

2.4 ceramic ferrule - ေျမက်က္ကရြတ္သည္၊ ဝရိမ္တို႔လို႔၊ သံအရည္ေပ်ာ္ေသာအခါ၊ သံရည္ပူမ်ား၊ မစင္ေအာင္၊ ကာထားေပးပါသည္။

2.5 shear connection ဟူသည္၊ ေအာက္ပါ ၅ မ်ိဳးကို၊ ဆက္စပ္ေပးထားျခင္းျဖစ္ပါသည္။

a. shear stud,

b. steel decking sheet,

c. slab rebar or steel mesh,

d. concrete slab, and

e. steel beam top flange

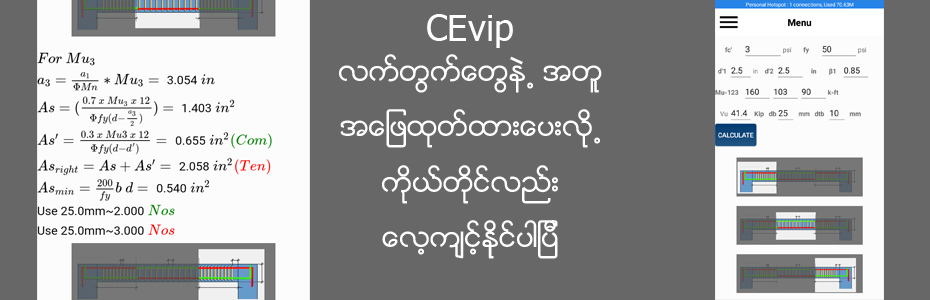

3. Design (ကြကိုဖတ္ပါေလ။)

4. အၾကံျပဳ ခ်က္(၉)ခ်က္။

4.1 welding မတို႔မီ၊ Steel deck ၏၊ မ်က္ႏွာျပင္ကို၊ သန္႔ရွင္းေရး ျပဳ လုပ္ပါ။

4.2 steel deck ခင္းၿပီးေနာက္၊ ၄င္း၏မ် က္ႏွာျပင္ေပၚသို႔၊ ညစ္ေပေနေသာ၊

အညစ္အေၾကးမ်ား၊ ေဆးစက္မ်ား၊ ဆီမ်ား၊ ေရမ်ား၊ မက် ေရာက္ေအာင္၊ ဂရုျပဳ ပါ။

4.3 လုပ္ငန္းမစတင္မီ၊ shears stud အနည္းငယ္ကို၊ အစမ္းတို႔ၾကည့္ပါ။

4.4 steel construction ၏ hardness မ်ားသည္၊ တေနရာႏွင့္တေနရာ၊

မတူညီမႈမ်ား၊ ျဖစ္ခ်င္လည္း၊ ျဖစ္တပ္ပါသျဖင့္၊ မတူညီေသာေနရာမ်ားတြင္၊

ထပ္မံစမ္းသပ္တို႔ၾကည့္ပါ။

4.5 welding gun ကို၊ steel deck ေပၚတြင္၊ မည္သည့္အခါမၽွမတင္ပါနဲ႔။ ေဘးအႏၲရာယ္ ျဖစ္တပ္ပါသည္။

4.6 welding တို႔ၿပီးရင္၊ stub သည္၊ 5mm ခန္႔၊ တိုသြားတပ္သည္ကို၊ သတိျပဳ ပါ။

4.7 shear stud အေပၚတြင္၊ concrete cover အလံုအေလာက္ရွိေအာင္၊ သတိျပဳ ပါ။

4.8 Ceramic ferrule မ်ားကို၊ ကြန္ကရစ္ေလာင္းကာနီးေသာ္၊ ဖယ္ထုတ္ျပစ္ပါ။

4.9 steel mesh တပ္ဆင္သည့္အခါ၊ Additional reinforcement ထည့္ေပးပါ။

1. What is dacking sheet

Metal Decking Sheets are made up of metals like aluminum, zinc

galvanized steel and are widely used as the strong and durable platforms

for floors, roofs etc. Metal Decking Sheets are used as the valuable

part of the construction as these are helpful to reduce excessive costs

involved. In industries, high-rise building structures, houses, these

sheets are much preferred.

Advantages:

1. 1. Reduced Concrete usage by reducing slab thickness due to its own tensile strength.

1. 2. Provide Strong and efficient permanent formwork and eliminates use of temporary formwork for concerete slab casting.

1.3. Reduced cost of construction.

1.4. Quick and easy installation.

1.5. Clean and less storage space required as compared to temporary scafolding formworks.

Application:

- Highrise Buildings

- Mezzanine Floors

- Steel Floor Decks

2. What is Shear Connector Stud?

Shear Connector Studs are designed to tie the concrete slab to the

steel beams and to resist shear loadings between the concrete slab and

steel beam in composite construction. This enables us to load up to 1000

kg/m² instead of the usual load which is much less. The procedure saves

time and therefore money as well due to its simplicity.

Each

weld cycle depends on the diameter of the fastener and the material

being joined and takes up to only 1 second. Welding currents range from

240 to 3000 amps.

2.1 The Shear Stud is made of steel and it is

delivered with a ceramic ferrule to ensure a good connection of the Stud

with the beam.

2.2 The shear Studs are available in different lengths and diameters .

2.3 The length of the Stud will be reduced by approximately 5mm during the welding process.

2.4 All Shear Studs are supplied with ferrules. The ferrules are made

of clay and able to withstand heat shock as well as high temperatures

without melting or breaking.

2.5 The shear connection of a composite beam comprises five elements that can all influence behaviour.

They include

2.5 shear connection ဟူသည္၊ ေအာက္ပါ ၅ မ်ိဳးကို၊ ဆက္စပ္ေပးထားျခင္းျဖစ္ပါသည္။

a. the shear stud connectors,

b. profiled steel sheeting(steel deck),

c. slab reinforcement (rebar or steel mesh) ,

d. concrete slab and

e. steel beam top flange.

3. Design

In such design the shear Stud connects the steel deck to the concrete slab.

Shear Stud Connectors are the most important element in Composite Beam

design securing the concrete to steel structural components. Shear Stus

Connectors resist shear forces and increase shear loading capacity in

steel buildings,bridges,

Design of the shear stud connector is very important because

3.1- it affects the choice of a suitable ultimate strength design method for the composite beam

3.2-The economics and speed of construction

3.3-The stability of the steel beam

3.4-The safety of steel beam against collapsing

4. WELDING SHEAR STUD CONNECTOR NSTALLATION WELDING TIPS

The longitudinal shear connection between the steel section and the

concrete is provided by shear connectors, which normally take the form

of studs welded to the top of the steel section.

All connectors

should be capable of resisting uplift forces caused by the tendency for

the slab to separate from the beam as it bends.

In the case of shear studs this is achieved by the head of the stud.

Although shear connectors ensure adequate fixing of the decking to the beam, they are not needed simply to achieve this.

They should only be used when it is desired to achieve composite action between the slab and the steel beam.

4.1. The Steel deck surface should be cleaned before any welding process starts

4.2. After the installation of the steel deck the surface should not have any dirt, paint spill overs, oil or water.

4.3. In case of welding over the steel deck additional welding time and

the ampere of the electrical current should be taken into account. Few

shears stud should be tested before carrying on with the rest of the

welding.

4.4. Further testing should be carried out in different

parts of the surface as well; as the steel construction hardness may be

different

4.5. The welding gun should not be placed on the steel

deck at any time as there is risk of short circuit as it touches the

steel deck

4.6. After welding the shear stud loses some of its height they are about 5mm shorter

4.7. Sufficient concrete cover should be provided over the shear studs

4.8. Ceramic ferrules left over from the shear studding process can be

left distributed over the decking surface and lost within the concrete

pour.

4.9. Additional reinforcement in shallow places of the steel deck should be provided in addition to steel mesh installation.

#CredittoSayar_kyawlwinhtun

#Design_Age_FJ